Heterotrophic Cultivation

Heterotrophy works differently: algae are grown without light, using organic carbon sources such as sugars both for energy and growth.

This approach is especially convenient since it can yield considerably faster growth compared to autotrophy, but only some algae species are capable of performing it.

A major benefit is that it allows fast cultivation in closed, controlled bioreactors, though there are increased chances of contamination due to the presence of the organic carbon source.

Cost Optimization

A first strategy to reduce cost is utilizing industrial waste streams as carbon sources.

The cost of ventilation to supply oxygen and remove CO₂ produced during respiration, along with the carbon source, are important considerations in the process economics.

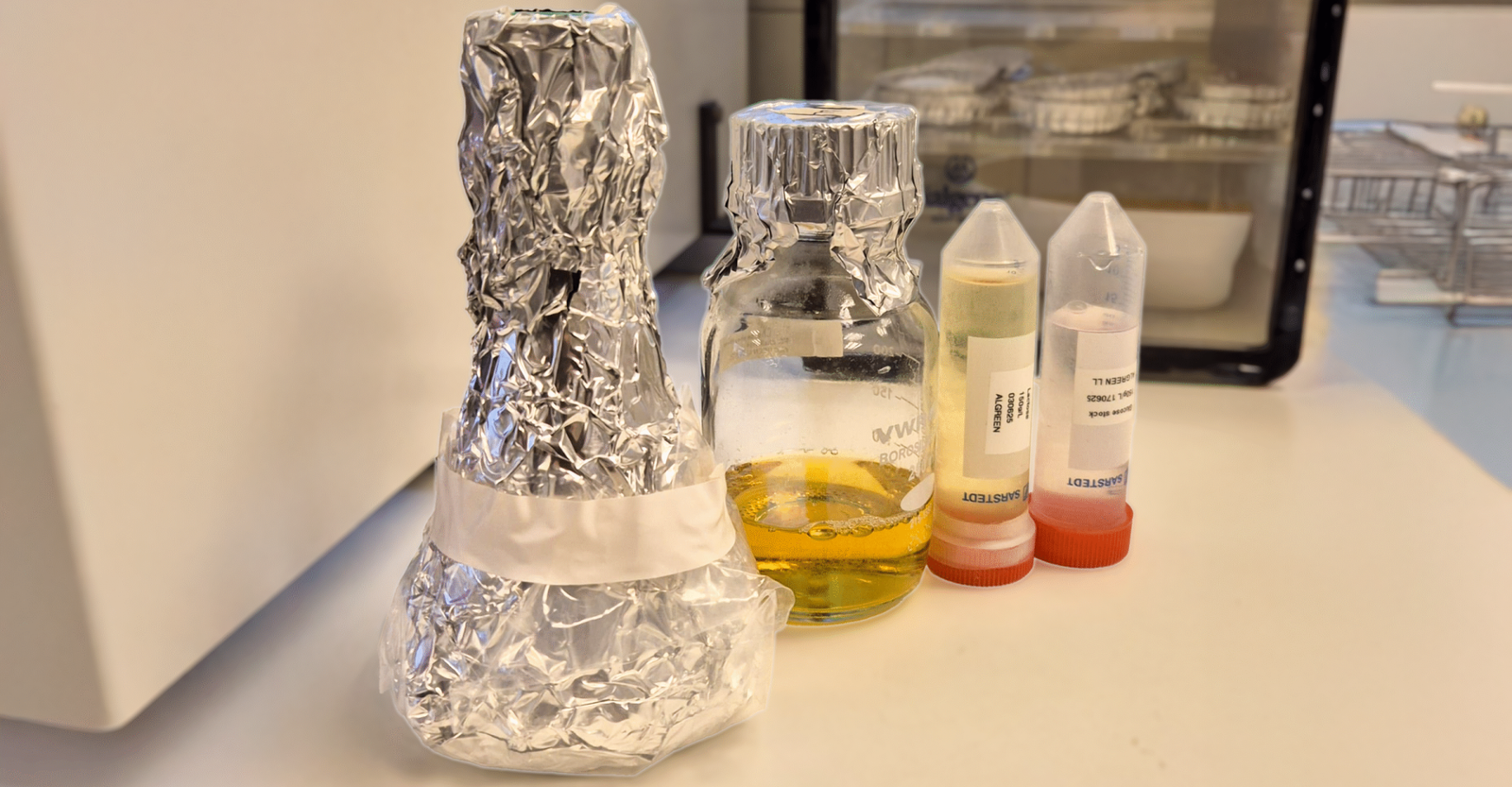

Algreen Experience

We have experience cultivating Galdieria and Chlorella species using heterotrophy, feeding algae such as Chlorella vulgaris with food industry by-products in controlled bioreactors for biomass production.

This approach lowers raw material costs and makes the process more sustainable.

Heterotrophic Cultivation

Heterotrophy works differently: algae are grown without light, using organic carbon sources such as sugars both for energy and growth.

This approach is especially convenient since it can yield considerably faster growth compared to autotrophy, but only some algae species are capable of performing it.

A major benefit is that it allows fast cultivation in closed, controlled bioreactors, though there are increased chances of contamination due to the presence of the organic carbon source.

Cost Optimization

A first strategy to reduce cost is utilizing industrial waste streams as carbon sources.

The cost of ventilation to supply oxygen and remove CO₂ produced during respiration, along with the carbon source, are important considerations in the process economics.

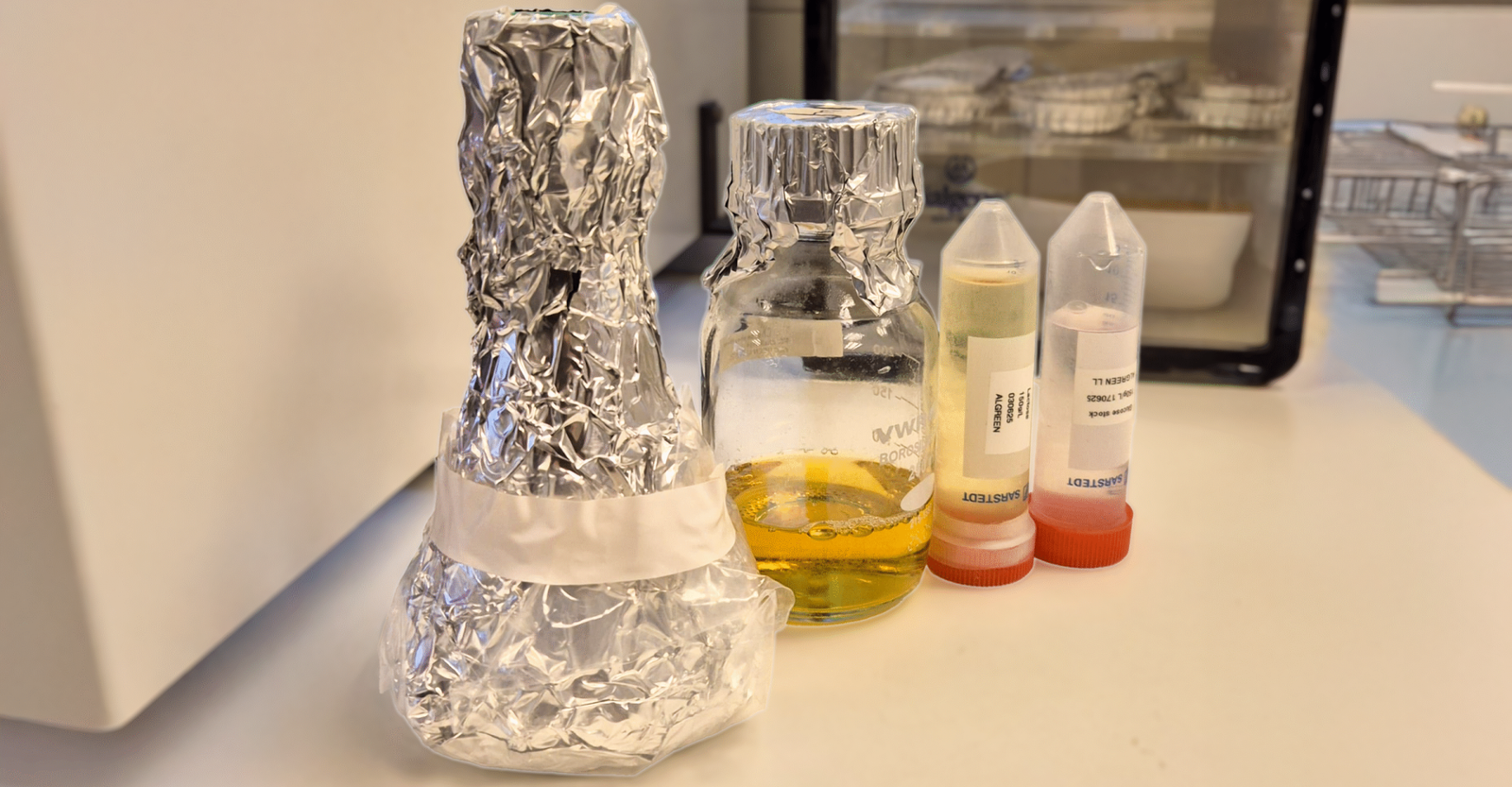

Algreen Experience

We have experience cultivating Galdieria and Chlorella species using heterotrophy, feeding algae such as Chlorella vulgaris with food industry by-products in controlled bioreactors for biomass production.

This approach lowers raw material costs and makes the process more sustainable.